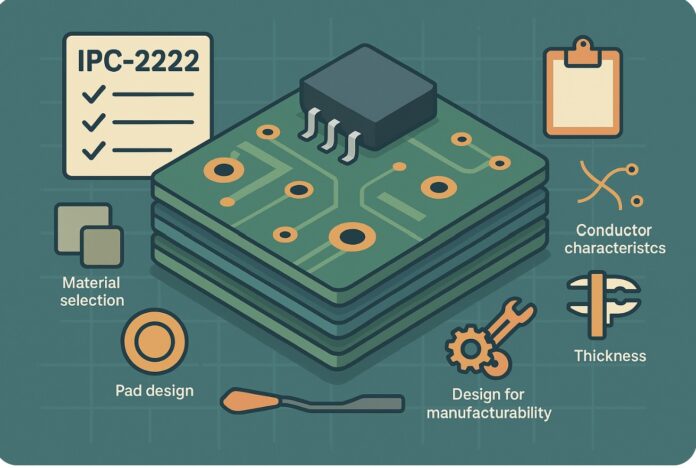

In today’s world of advanced electronics, the integrity of a printed circuit board (PCB) is fundamental to the performance of nearly every electronic device. Behind every successful and reliable PCB lies a well-thought-out design process, guided by internationally recognized standards. One such cornerstone in the industry is the IPC-2222 standard, which sets detailed design criteria for rigid organic PCBs. When engineers need to make informed decisions about PCB materials, layout, stack-up, and reliability, IPC-2222 provides the roadmap.

This article delves deep into the IPC-2222 standards, exploring their role in PCB design, the importance of selecting the right PCB material, and how these standards influence the broader field of electronic manufacturing.

Understanding IPC Standards

IPC (formerly known as the Institute for Interconnecting and Packaging Electronic Circuits) is a global trade association that develops standards for the electronics industry. The IPC-2220 series covers generic design standards for printed boards, and IPC-2222 specifically addresses sectional design standards for rigid organic printed boards.

The IPC-2222 standard outlines requirements that PCB designers should follow to ensure their boards are manufacturable, reliable, and meet their functional requirements across various applications.

What is IPC-2222?

IPC-2222 is part of the IPC-2220 series, which focuses on the design of printed boards and other forms of component mounting or interconnecting structures. IPC-2222 narrows its scope to the design of rigid organic PCBs, which are widely used in everything from consumer electronics to military systems.

It offers guidance on:

- Material selection

- Conductor characteristics

- Pad design

- Hole tolerancing

- Layer stack-up

- Mechanical constraints

- Design for manufacturability (DFM)

By adhering to IPC-2222 standards, PCB designers can ensure their boards are not only functional but also optimized for cost, yield, and long-term reliability.

PCB Material Considerations in IPC-2222

Material selection is one of the most critical aspects of PCB design. IPC-2222 addresses PCB material requirements in terms of electrical, mechanical, thermal, and environmental performance.

Key PCB material considerations include:

1. Dielectric Constant (Dk)

Affects signal speed and impedance. IPC-2222 helps define tolerances for controlled impedance traces.

2. Thermal Conductivity and Coefficient of Thermal Expansion (CTE)

These are crucial for applications that involve temperature cycling. Mismatches between board materials and components can cause stress and eventual failure.

3. Glass Transition Temperature (Tg)

Determines the temperature at which the material transitions from a rigid to a more flexible state. Higher Tg materials are preferred in high-temperature environments.

4. Moisture Absorption

High humidity can degrade electrical properties. IPC-2222 specifies acceptable moisture absorption rates for certain classes of PCBs.

5. Flammability and Regulatory Compliance

Materials must often meet UL 94V-0 ratings and comply with RoHS and REACH standards. IPC-2222 ensures designers are aware of these constraints.

Popular PCB materials aligned with IPC-2222 include:

- FR-4: The standard material for most PCBs, offering a balance of performance and cost.

- Polyimide: Offers high thermal performance and reliability.

- High-Frequency Laminates: Used in RF and microwave applications.

- Halogen-Free Materials: Preferred for environmentally friendly and safe electronics.

IPC-2222 Classes of Performance

To meet different use-case requirements, IPC-2222 divides PCB designs into three performance classes:

- Class 1: General Electronic Products

- Low-cost consumer electronics with limited functional life.

- Low-cost consumer electronics with limited functional life.

- Class 2: Dedicated Service Electronic Products

- Devices requiring extended performance and uninterrupted service (e.g., appliances, business equipment).

- Devices requiring extended performance and uninterrupted service (e.g., appliances, business equipment).

- Class 3: High-Reliability Electronic Products

- Mission-critical systems like aerospace, medical, or military applications.

Each class has different tolerances and specifications. Designers must select PCB materials and design features that comply with the appropriate performance class.

Key Design Areas Covered by IPC-2222

IPC-2222 addresses many technical aspects of PCB design. Here are the most significant:

1. Conductor Width and Spacing

Defines minimum spacing between traces and required widths for current carrying capacity and signal integrity.

2. Pad and Land Design

Proper pad sizes ensure strong solder joints and mechanical durability.

3. Via Design and Hole Sizes

Guidance on plating, aspect ratios, and tolerances for plating through holes and vias.

4. Layer Stack-Up

IPC-2222 helps define the number of layers, dielectric thickness, and copper weights for effective power delivery and signal transmission.

5. Design for Manufacturability (DFM)

DFM features ensure that designs are easy to fabricate, assemble, and test. IPC-2222 offers guidelines on clearances, tool allowances, and board outlines.

Integration with Other IPC Standards

IPC-2222 is not a standalone standard. It works in harmony with other IPC documents, including:

- IPC-2221: Generic standard for all board types.

- IPC-A-600: Acceptability of Printed Boards.

- IPC-A-610: Acceptability of Electronic Assemblies.

- IPC-7351: Surface Mount Design and Land Pattern Standard.

This integrated approach helps ensure a complete and compliant electronic product design and manufacturing process.

How IPC-2222 Supports Modern Electronic Design

As designs become more complex and compact, standards like IPC-2222 are critical for ensuring quality and consistency. Here’s how IPC-2222 plays a role in today’s fast-paced electronics world:

- Enables Global Manufacturing: By following IPC-2222, designs are compatible with fabrication and assembly facilities worldwide.

- Supports Automation and Inspection: Automated optical inspection (AOI) and X-ray systems rely on predictable and standard board layouts.

- Boosts First-Pass Yield: Proper tolerances and material choices reduce the risk of rework or rejection.

- Aids in Certification and Testing: Regulatory bodies often reference IPC standards when approving devices for sale or use.

Challenges Addressed by IPC-2222

- Miniaturization

- Helps balance trace density and spacing requirements while ensuring reliability.

- Helps balance trace density and spacing requirements while ensuring reliability.

- High-Speed and High-Frequency Design

- Material parameters such as Dk and Df become critical. IPC-2222 guides designers on stack-up and trace impedance.

- Material parameters such as Dk and Df become critical. IPC-2222 guides designers on stack-up and trace impedance.

- Thermal Management

- Provides strategies for layer distribution, copper weights, and via designs to handle heat dissipation.

- Provides strategies for layer distribution, copper weights, and via designs to handle heat dissipation.

- Environmental Conditions

- Ensures materials and finishes can withstand humidity, temperature, and chemical exposure.

- Ensures materials and finishes can withstand humidity, temperature, and chemical exposure.

Conclusion

The IPC-2222 standard is an essential resource for anyone involved in the design and development of rigid PCBs. From PCB material selection to trace routing and mechanical tolerances, IPC-2222 provides a solid foundation for achieving high-quality, manufacturable, and reliable electronic products.

By incorporating these guidelines early in the design process, engineers can reduce costly redesigns, streamline production, and meet global quality benchmarks. Whether you’re developing consumer gadgets or mission-critical systems, IPC-2222 empowers you to design with confidence.