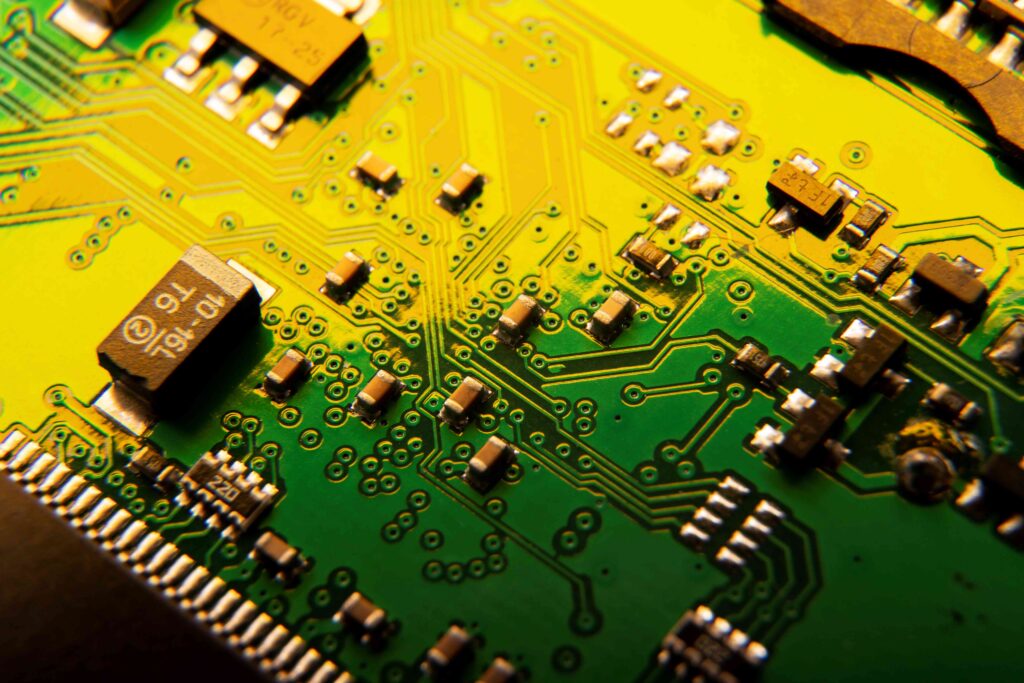

In the rapidly evolving world of technology, environmental sustainability is a growing priority across industries, particularly in electronics manufacturing. One of the most impactful changes in this sector is the adoption of lead-free soldering for Printed Circuit Boards (PCBs). This shift aims to reduce environmental and health risks associated with lead, while ensuring compliance with stringent global regulations. This article explores the essentials of lead-free soldering, its effects on PCB design, PCB prototyping, and manufacturing, and the challenges and best practices associated with its implementation.

What is Lead-Free Soldering?

Lead-free soldering refers to the process of joining electronic components to a PCB without using solder alloys that contain lead. Traditional solder, which typically consists of 60% tin and 40% lead (SnPb), has been widely used due to its excellent mechanical and electrical properties. However, lead is highly toxic and poses significant health risks and environmental challenges, leading to strict regulations limiting its use.

The most common lead-free solder alloys include:

- Tin-Silver-Copper (SAC): A popular choice with good performance characteristics.

- Tin-Copper (SnCu): Used for less demanding applications.

- Bismuth-based Alloys: Often used for specific low-temperature applications.

The Environmental and Regulatory Push

The transition to lead-free soldering has been driven by international regulations such as the Restriction of Hazardous Substances (RoHS) directive in the European Union, which bans the use of lead and other hazardous substances in electrical and electronic equipment. Compliance with such regulations is now a key consideration for any company involved in PCB manufacturing and assembly.

Lead-free soldering not only meets these regulatory requirements but also supports corporate social responsibility goals, reduces the risk of lead contamination, and aligns with consumer demand for eco-friendly products.

Impact on PCB Design

Switching to lead-free soldering significantly influences PCB design. Engineers must consider the higher melting points and different mechanical properties of lead-free solders. This impacts materials, PCB layout, and thermal management.

Key considerations include:

- Material Selection: Lead-free solder requires PCB laminates that can withstand higher reflow temperatures. High-temperature FR-4 laminates are commonly used for this purpose.

- Component Compatibility: Not all electronic components are compatible with lead-free soldering. Designers must ensure that components are rated for higher reflow temperatures.

- Thermal Management: Increased temperatures can cause warping or damage to the PCB. Adequate heat dissipation techniques, such as thermal vias and heat sinks, must be incorporated during the design phase.

Challenges in PCB Prototyping

PCB prototyping is an essential step in electronics development, allowing designers to test and validate their designs before mass production. Transitioning to lead-free soldering introduces unique challenges during this stage, including:

- Solder Joint Reliability: Lead-free solder joints are generally more brittle than leaded ones, increasing the risk of cracks or failures in high-stress environments.

- Reflow Profile Optimization: Achieving a precise reflow profile is critical for successful lead-free soldering. The temperature profile must account for the higher melting points of lead-free alloys.

- Equipment Compatibility: Soldering equipment must be capable of operating at higher temperatures. Companies may need to invest in or upgrade reflow ovens, wave soldering machines, and inspection systems.

Benefits of Lead-Free Soldering

Despite the challenges, lead-free soldering offers numerous benefits:

- Environmental Safety: Eliminates lead-related toxicity, reducing health and ecological risks.

- Regulatory Compliance: Ensures adherence to global standards such as RoHS, enabling market access in regions with strict environmental laws.

- Improved Marketability: Eco-friendly products appeal to environmentally conscious consumers and businesses.

Best Practices for Lead-Free PCB Manufacturing

To successfully implement lead-free soldering, manufacturers and designers should adopt best practices that address the unique requirements of lead-free processes. These include:

- Comprehensive Training: Educate employees on the differences between leaded and lead-free soldering, including handling higher temperatures and inspecting solder joints.

- Optimized Design Rules: Update PCB design guidelines to incorporate thermal relief pads, proper component placement, and adequate spacing to mitigate the effects of higher reflow temperatures.

- Advanced Inspection Techniques: Utilize automated optical inspection (AOI) and X-ray inspection to ensure the quality of lead-free solder joints.

- Material Testing: Conduct thorough testing of PCB materials and components to confirm their suitability for lead-free processes.

- Collaboration with Suppliers: Work closely with suppliers to source lead-free materials and components that meet quality and reliability standards.

Alternatives to Lead-Free Soldering

While lead-free soldering is the most common solution for achieving environmental compliance, alternative methods are also available:

- Conductive Adhesives: Used in specific low-power applications as an alternative to solder.

- Press-Fit Technology: Eliminates the need for solder by mechanically pressing components into the PCB.

These alternatives, however, may not be suitable for all applications and typically require specialized design and manufacturing techniques.

Future Trends in Lead-Free PCB Assembly

The electronics industry continues to innovate and improve lead-free soldering technologies. Emerging trends include:

- Improved Alloys: Research is ongoing to develop lead-free solder alloys with enhanced mechanical and thermal properties.

- Advanced Soldering Techniques: Methods such as laser soldering and selective soldering are being refined for lead-free applications.

- Sustainability Metrics: Companies are adopting comprehensive sustainability metrics to evaluate and minimize the environmental impact of their entire PCB manufacturing process.

Conclusion

Lead-free soldering in PCBs is not just a regulatory requirement; it is a vital step toward a sustainable future. By understanding its implications on PCB design, PCB prototyping, and manufacturing processes, companies can navigate the challenges and leverage the benefits of this environmentally friendly technology. Embracing lead-free soldering not only ensures compliance with global standards but also demonstrates a commitment to health, safety, and sustainability in the electronics industry.