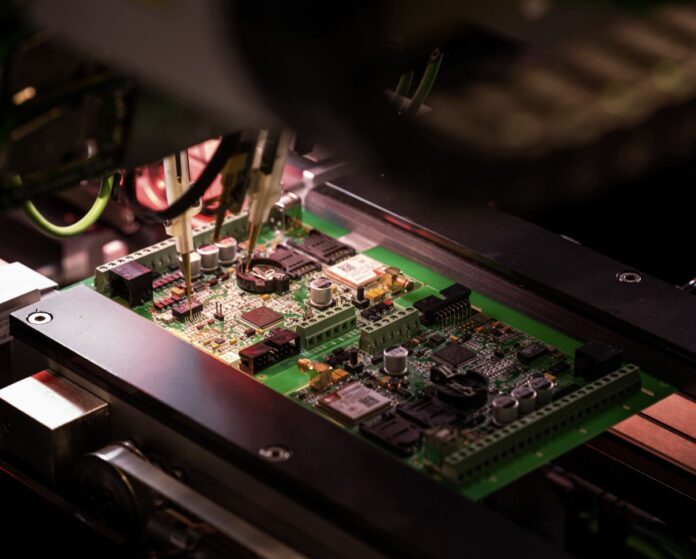

From small digital devices to big electronic machines, the main basis is the printed circuit boards. Starting from smartphones to computers, PCBs do a great job of connecting various electronics in order for them to work seamlessly. In that respect, knowing how printed circuit boards are made helps both the professional engineer and hobbyists alike to build better electronic systems while at the same time ensuring quality and reliability. In this article, we take you through a step-by-step guide in detail through the process of PCB manufacturing, right from its design to the finished product.

What is a Printed Circuit Board (PCB)?

A printed circuit board is a thin board made of insulating material, typically fiberglass, on which conductive pathways are etched or printed. These pathways connect various electronic components, such as resistors, capacitors, diodes, and integrated circuits, facilitating their interaction within the device. PCBs can be single-sided, double-sided, or multi-layered, depending on the complexity of the electronic design.

Importance of PCB Manufacturing

PCB manufacturing is a critical process in the electronics industry. It impacts the performance, reliability, and cost-effectiveness of electronic devices. A well-designed and manufactured PCB can improve signal integrity, reduce electromagnetic interference, and enhance thermal management. Consequently, understanding the PCB manufacturing process is essential for anyone involved in electronic design, whether in a professional capacity or as a hobbyist.

PCB Manufacturing Process: Step-by-Step Guide

Step 1: Electronic Design

The first step in the PCB manufacturing process is the electronic design. This involves creating a schematic diagram that represents how the various electronic components will be connected. Engineers typically use specialized software, such as Eagle, Altium Designer, or KiCAD, to create the schematic.

Key Considerations:

- Component Selection: Choose the right components based on size, power requirements, and functionality.

- Schematic Layout: Ensure that the schematic accurately represents the desired electronic functionality.

- Design Rules: Adhere to design rules for trace widths, spacing, and component placement to avoid issues during manufacturing.

Step 2: PCB Layout Design

Once the schematic is complete, the next step is to design the PCB layout. This involves arranging the components on the board and routing the conductive pathways (traces) that connect them.

Key Considerations:

- Layer Count: Determine the number of layers needed based on the complexity of the design. Single-layer boards are simpler, while multi-layer boards can accommodate more complex designs.

- Trace Width and Spacing: Follow guidelines for trace widths and spacing to ensure adequate current-carrying capacity and to minimize interference.

- Component Placement: Optimize the placement of components to minimize trace lengths and improve signal integrity.

Step 3: Generating Gerber Files

After finalizing the PCB layout, the next step is to generate Gerber files. These files contain all the information needed for the PCB manufacturing process, including layer specifications, drill holes, and component placement.

Key Considerations:

- File Formats: Ensure that Gerber files are generated in standard formats compatible with PCB manufacturers.

- DRC Checks: Perform Design Rule Checks (DRC) to identify any potential issues before sending the files for manufacturing.

Step 4: PCB Manufacturing

With the Gerber files in hand, it’s time to begin the actual PCB manufacturing process. This involves several key steps:

4.1 Material Selection

Choose the right materials for the PCB. Common materials include FR-4 (a type of fiberglass), polyimide (for flexible PCBs), and aluminum (for high-power applications).

4.2 Printing the PCB Layers

The first physical step in PCB manufacturing is printing the layers onto the chosen substrate material. This is typically done using a process called photoengraving, where a photosensitive film is applied to the board.

4.3 Etching

After printing, the next step is etching. This process removes the unwanted copper from the board, leaving only the desired copper traces. This is typically done using a chemical etchant.

4.4 Drilling

Once the etching is complete, holes are drilled into the PCB for component leads and vias. Automated drilling machines are usually employed for precision.

4.5 Plating and Coating

After drilling, the PCB undergoes plating to enhance conductivity and protect against corrosion. A layer of solder mask is then applied to prevent solder from bridging between traces.

Step 5: Surface Finish

The next step in the PCB manufacturing process is applying a surface finish to the exposed copper pads. This is crucial for solderability and can involve various finishes, such as:

- HASL (Hot Air Solder Leveling): A common surface finish that provides good solderability.

- ENIG (Electroless Nickel Immersion Gold): A more expensive option that offers excellent corrosion resistance and solderability.

- OSP (Organic Solderability Preservative): A cost-effective finish that protects copper pads without adding thickness.

Step 6: Assembly

Once the PCB is manufactured, it’s time for assembly. This process involves placing components on the PCB and soldering them in place. There are several assembly methods, including:

- Through-Hole Technology (THT): Components with leads are inserted into holes and soldered on the opposite side.

- Surface Mount Technology (SMT): Components are mounted directly onto the surface of the PCB.

Step 7: Testing

After assembly, the PCB must undergo rigorous testing to ensure functionality and reliability. This may include:

- Visual Inspection: Checking for soldering defects, misaligned components, and other physical issues.

- Functional Testing: Verifying that the PCB operates as intended under various conditions.

- Automated Testing: Using specialized equipment to conduct tests on multiple boards simultaneously.

Step 8: Quality Assurance

Quality assurance is a final but crucial step in the PCB manufacturing process. This ensures that the PCBs meet industry standards and customer specifications. Quality control measures may include:

- IPC Standards Compliance: Adhering to industry standards set by the Institute for Printed Circuits (IPC) for quality and reliability.

- Environmental Testing: Conducting tests to assess performance under different environmental conditions.

Step 9: Delivery

Once the PCBs have passed all quality assurance tests, they are packaged and delivered to the client or manufacturer. Proper packaging is essential to prevent damage during transportation.

Conclusion

The PCB manufacturing process is a complex yet fascinating journey that transforms electronic designs into functional circuit boards. From initial electronic design to final delivery, each step plays a crucial role in ensuring the quality and reliability of the end product. Understanding this process is invaluable for anyone involved in electronic design, whether in a professional capacity or as a hobbyist.

By familiarizing yourself with the PCB manufacturing process, you can make informed decisions that enhance your designs, reduce costs, and improve the performance of your electronic devices. Whether you’re designing a simple gadget or a sophisticated piece of equipment, a solid grasp of PCB manufacturing will undoubtedly serve you well.

As technology continues to evolve, the demand for high-quality PCBs will only increase, making it essential to stay abreast of the latest trends and advancements in PCB manufacturing. Whether you are a seasoned engineer or a newcomer to the field, understanding these processes will empower you to create innovative and reliable electronic solutions.