What is CF-004?

CF-004 is a specialized PCB board material widely used in electronic design and circuit board manufacturing. It is known for its high-performance dielectric properties, making it an ideal choice for high-frequency applications, RF circuits, and other advanced PCB assemblies.

In the realm of PCB manufacturing, selecting the right material significantly impacts the performance, longevity, and efficiency of an electronic device. CF-004 is often used as a base material for multilayer PCBs, offering excellent mechanical stability, heat resistance, and electrical insulation.

Key Properties of CF-004 PCB Material:

- High dielectric strength: Ensures minimal signal loss and optimal conductivity.

- Thermal stability: Withstands high operating temperatures, crucial for industrial and RF applications.

- Low dissipation factor: Maintains signal integrity in high-speed circuits.

- Mechanical robustness: Provides excellent dimensional stability under various environmental conditions.

Due to these properties, CF-004 is favored in the telecommunications, aerospace, and automotive industries, where reliability and efficiency are paramount.

CF-004 Equivalent Materials

For manufacturers and engineers looking for CF-004 equivalents, several high-performance PCB materials offer similar or enhanced properties. Some widely used alternatives include:

1. FR-4 (Flame Retardant 4)

- The most common fiberglass-reinforced epoxy laminate used in PCB manufacturing.

- Offers good electrical insulation, but with slightly lower thermal stability than CF-004.

- Suitable for consumer electronics, industrial control systems, and general-purpose PCBs.

2. Rogers RO4000 Series

- A high-performance PCB material known for its low loss and high-frequency capabilities.

- Used in RF, microwave, and telecommunication applications.

- Provides better thermal conductivity compared to CF-004.

3. Taconic TLY Series

- High-frequency laminates offering superior dielectric performance.

- A preferred choice for antenna and radar applications.

4. Isola 370HR

- High-performance lead-free material with enhanced thermal and electrical properties.

- Used in multilayer PCB designs where high reliability is required.

While CF-004 remains a preferred material in many designs, engineers should assess factors like cost, thermal stability, and RF performance when selecting an equivalent.

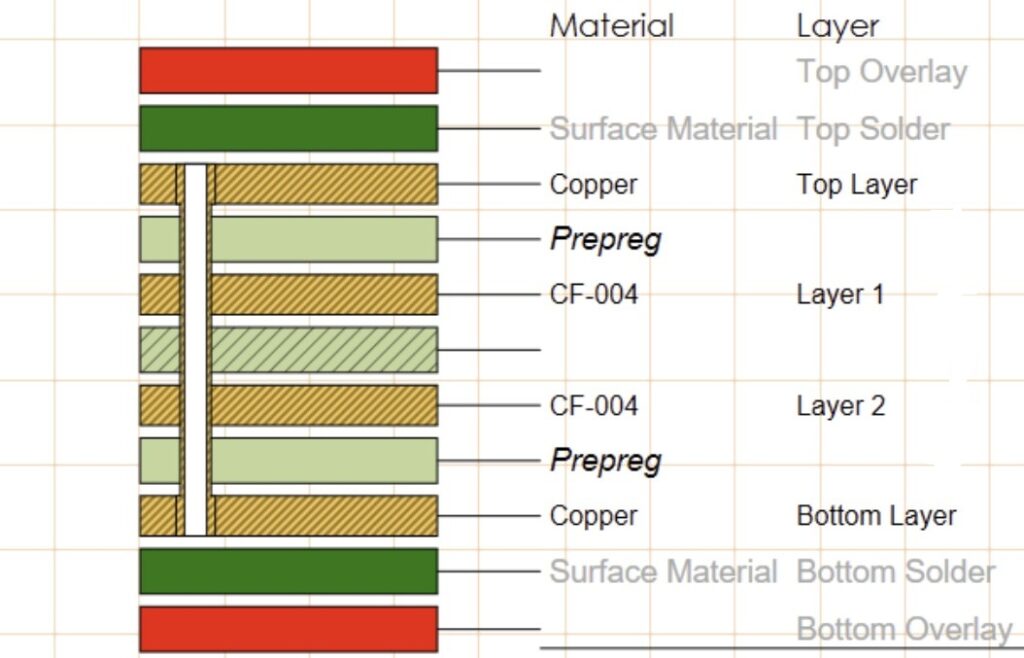

CF-004 in Altium Designer

Altium Designer is one of the most powerful PCB design software tools, allowing engineers to work with various PCB materials, including CF-004.

How to Use CF-004 in Altium Designer:

- Material Selection:

- Within Altium’s Stackup Manager, users can define CF-004 as the core material.

- Set the dielectric constant and thickness based on the manufacturer’s datasheet.

- Layer Stackup Configuration:

- CF-004 can be used as a dielectric layer in high-frequency PCB designs.

- It provides better signal integrity in multi-layer PCBs, especially in RF circuits.

- Thermal Analysis & Simulation:

- Altium Designer enables engineers to simulate the thermal and electrical performance of CF-004 before manufacturing.

- This helps in reducing design errors and optimizing circuit performance.

- Gerber File Generation:

- Once the PCB layout using CF-004 is finalized, the Gerber files can be exported for manufacturing.

By integrating CF-004 into Altium Designer, engineers ensure that their designs meet high-performance standards while optimizing signal integrity and thermal management.

CF-004 and Copper Cladding

Copper plays a crucial role in PCB design, and when combined with CF-004, it creates a highly efficient circuit board for high-frequency and power applications.

Why Copper Cladding is Essential:

- Enhanced Conductivity: Copper ensures minimal resistance, leading to better electrical performance.

- Heat Dissipation: High-quality copper-clad CF-004 boards dissipate heat effectively, preventing thermal damage.

- Signal Integrity: In RF applications, smooth copper surfaces reduce skin effect losses, ensuring better performance at high frequencies.

Common Copper Thickness for CF-004 PCBs:

| Copper Weight | Thickness (oz/ft²) | Applications |

| 0.5 oz | 17 μm | Lightweight PCBs, sensors |

| 1.0 oz | 35 μm | Standard PCB applications |

| 2.0 oz | 70 μm | High-power circuits, automotive |

| 3.0+ oz | 105+ μm | Heavy-duty power applications |

For high-speed and RF applications, using low-profile or rolled annealed (RA) copper on CF-004 substrates further enhances electrical performance.

Conclusion: Why CF-004 is a Game-Changer in PCB Manufacturing

CF-004 is a versatile, high-performance PCB material widely used in electronic design for its thermal stability, low dielectric loss, and excellent mechanical properties. Its applications range from telecommunications and RF circuits to automotive and aerospace industries.

When selecting PCB board materials, engineers should consider CF-004 for its reliability, but also explore equivalents like FR-4, Rogers RO4000, Taconic TLY, and Isola 370HR to match specific project requirements.

By integrating CF-004 into Altium Designer, designers can optimize signal integrity and thermal management, ensuring their PCB layouts meet high industry standards. For enhanced electrical conductivity and durability, CF-004 with copper cladding is an excellent choice, particularly in high-frequency and power applications. As technology advances, CF-004 will continue to play a critical role in shaping the future of high-performance PCB manufacturing.