Printed Circuit Boards (PCBs) are at the heart of virtually all electronic devices, providing the foundation for electrical connectivity and functionality. In modern electronics manufacturing, wave soldering stands out as one of the most crucial PCB assembly techniques. This article delves into the essentials of wave soldering while also exploring its relationship with PCB design, PCB prototyping, and other critical aspects of the electronics manufacturing process.

What is Wave Soldering?

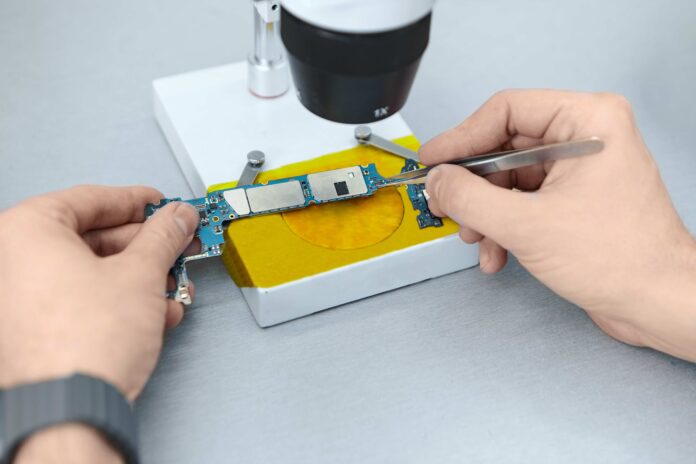

Wave soldering is a mass soldering process used to affix electronic components to the surface of a PCB. It is particularly well-suited for through-hole technology (THT) components but can also handle certain surface-mount components with appropriate PCB design considerations. During this process, a “wave” of molten solder is created, which passes over the underside of the PCB, soldering the component leads to the board’s pads.

The Wave Soldering Process

The wave soldering process consists of several key steps:

1. Flux Application

Flux is applied to the PCB to clean the component leads and pad surfaces, promoting better solder adhesion and reducing the risk of oxidation.

2. Preheating

The PCB is preheated to ensure thermal stability, minimizing thermal shock when exposed to molten solder. This step also activates the flux.

3. Solder Wave

PCB is passed over a wave of molten solder. The solder adheres to the fluxed areas, creating reliable connections between the component leads and the PCB pads.

4. Cooling

After soldering, the PCB is cooled to solidify the solder joints and secure the components in place.

Benefits of Wave Soldering

Wave soldering is a preferred method for PCB assembly due to its efficiency and reliability, particularly for high-volume production. Key benefits include:

- Consistency: Automated soldering ensures uniform quality across multiple PCBs.

- Speed: The process is rapid and ideal for mass production.

- Cost-Effectiveness: Economical for assembling large quantities of boards.

- Compatibility: Works well with both through-hole and some surface-mount components.

Wave Soldering and PCB Design

The success of wave soldering heavily relies on optimal PCB design. Design considerations include:

- Component Placement: Components must be oriented to minimize soldering defects. Sensitive components are often positioned away from the solder wave’s leading edge.

- Solder Mask: Proper solder mask design prevents solder bridges and ensures clean connections.

- Pad Sizes and Layout: Uniform pad sizes and strategic placement reduce soldering issues.

- Panelization: For high-volume production, multiple PCBs can be designed into a single panel to streamline the process.

Designers must also account for factors like thermal relief, ground planes, and via placement to ensure effective soldering and board functionality.

Wave Soldering vs. Reflow Soldering

While wave soldering is ideal for THT components, reflow soldering is the dominant technique for surface-mount technology (SMT). Reflow soldering uses a solder paste that is melted during a controlled heating process, making it more suitable for intricate SMT designs.

Comparing the two:

| Aspect | Wave Soldering | Reflow Soldering |

| Suitable for | THT and some SMT | Primarily SMT |

| Production Volume | High | Medium to High |

| Equipment Cost | Moderate | High |

| Solder Type | Molten Solder Wave | Solder Paste |

Wave Soldering and PCB Prototyping

During the PCB prototyping phase, wave soldering is less commonly used due to the smaller scale and lower volume of boards. Prototypes often rely on hand soldering or selective soldering techniques to save costs and allow for design adjustments. However, once a design is finalized and moves to production, wave soldering becomes a viable option for efficient assembly.

Key considerations during prototyping include:

- Testing and Debugging: Prototypes need to be easily testable to validate designs.

- Material Selection: Choosing the right materials for PCB substrates, components, and solder ensures scalability.

- Design Optimization: Iterative prototyping allows engineers to refine designs for manufacturability and compatibility with wave soldering.

Related Topics in PCB Assembly

To fully appreciate wave soldering, it’s essential to understand its connection to broader PCB assembly processes and related topics:

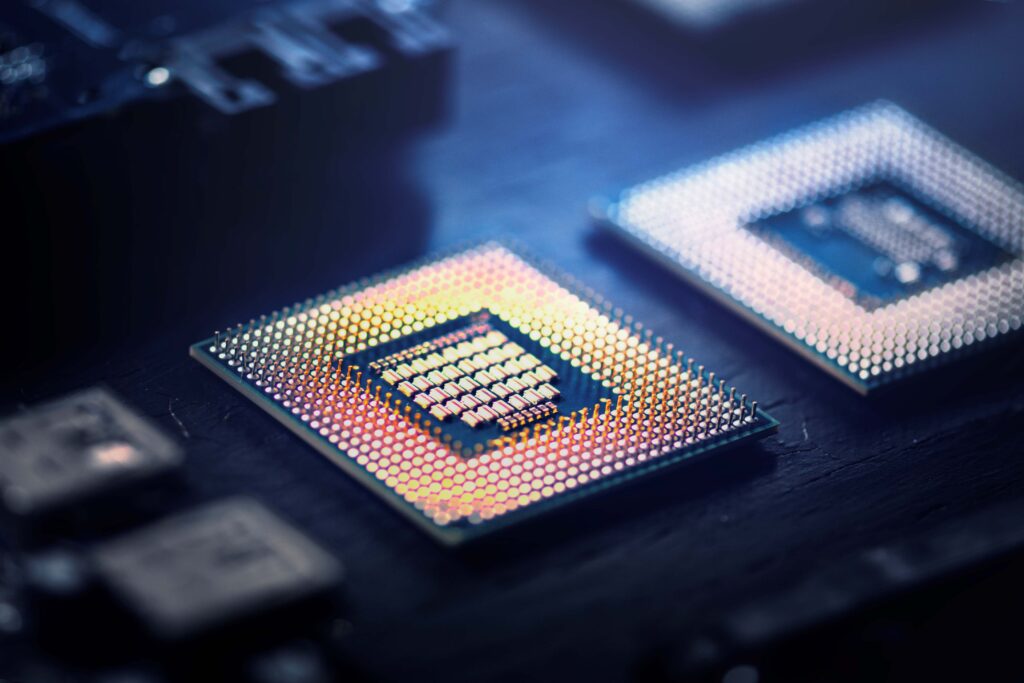

1. Surface Mount Technology (SMT)

Although wave soldering is used for THT components, SMT dominates modern PCB designs. Techniques like reflow soldering complement wave soldering in hybrid designs.

2. Solder Paste vs. Solder Wave

The choice between solder paste (for reflow soldering) and molten solder (for wave soldering) impacts the board’s design and assembly process. Proper PCB design considers these factors from the outset.

3. Selective Soldering

Selective soldering is an alternative to wave soldering, used for boards with mixed THT and SMT components. It involves targeting specific areas with solder instead of covering the entire board.

4. Design for Manufacturability (DFM)

Ensuring a PCB design is manufacturable is critical. DFM principles guide designers to create boards that are compatible with wave soldering and other assembly methods.

Challenges in Wave Soldering

Despite its advantages, wave soldering has its challenges:

- Solder Bridging: Excess solder can create unintended connections between pads.

- Component Movement: Misaligned components can lead to defects.

- Thermal Stress: Improper preheating can damage sensitive components.

- Environmental Concerns: Lead-based solder poses environmental risks, driving the adoption of lead-free alternatives.

Mitigating these challenges requires precise process control, regular equipment maintenance, and adherence to design guidelines.

Conclusion

Wave soldering remains a cornerstone of PCB assembly, offering a reliable and efficient solution for high-volume production of through-hole and hybrid boards. Its success is closely tied to meticulous PCB design, strategic PCB prototyping, and adherence to modern manufacturing standards.

As technology evolves, wave soldering continues to adapt, incorporating advancements like lead-free soldering to meet environmental regulations and the demands of increasingly complex PCB designs. By understanding and leveraging this key technique, manufacturers can ensure robust, high-quality electronic assemblies that meet the needs of today’s competitive market.