From simple phones to the most complicated machinery, Printed Circuit Boards form the backbone of modern electronic design. In the large domain of PCB manufacturing, Surface-Mount Technology has emerged as a game-changing facility in simplifying the production process and enhancing performance and reliability. The working of SMT assembly, its advantages, and its influence on electronic design and PCB production are discussed here.

Understanding SMT and Its Role in PCB Production

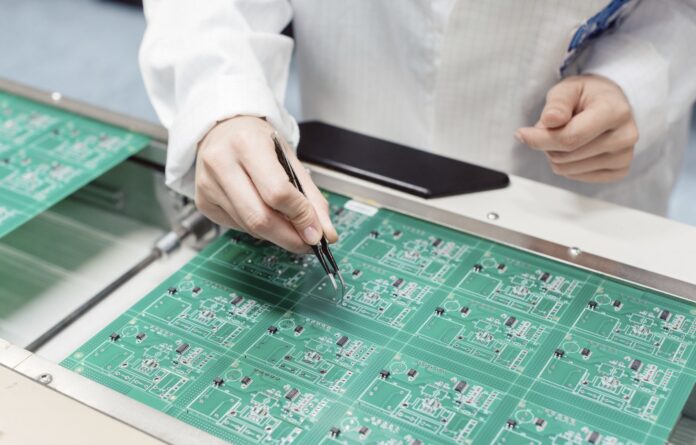

Surface-Mount Technology (SMT) is a method for assembling electronic components directly onto the surface of a printed circuit board. Unlike traditional through-hole technology, where components are inserted into holes and soldered on the opposite side, SMT allows for a more compact design, facilitating the placement of components on both sides of the PCB. This technique reduces the overall size and weight of electronic devices while enabling higher component density.

The Basics of Printed Circuit Boards

At the core of any electronic device lies the Printed Circuit Board. A PCB serves as a foundation that connects electronic components using conductive pathways, etched from copper sheets laminated onto a non-conductive substrate. These components can include resistors, capacitors, and integrated circuits.

When designing a PCB, engineers must consider factors such as signal integrity, thermal management, and manufacturability. The transition from traditional assembly methods to SMT has significantly streamlined these processes, allowing for improved designs and faster production times.

The Advantages of Surface-Mount Technology

The adoption of SMT in PCB production offers several compelling advantages:

1. Space Efficiency

SMT components are generally smaller than their through-hole counterparts. This allows for lighter and more compact PCBs, enabling the design of smaller devices. As the demand for portable electronics rises, this aspect of SMT becomes increasingly important.

2. Enhanced Performance

SMT facilitates the use of high-frequency components, which is crucial in today’s fast-paced technological landscape. By minimizing lead lengths and improving electrical performance, SMT helps reduce parasitic capacitance and inductance, leading to better signal integrity.

3. Faster Production Processes

SMT assembly is often automated, significantly speeding up the manufacturing process. Automated pick-and-place machines can quickly position thousands of components per minute on a PCB, drastically reducing labor costs and production time compared to manual assembly techniques.

4. Improved Reliability

Solder joints in SMT tend to be more reliable than those in traditional through-hole technology. The surface-mount connections lead to better mechanical bonding and thermal stability. Furthermore, SMT’s ability to use reflow soldering processes helps mitigate issues like thermal shock and eliminates the risk of cold solder joints.

5. Design Flexibility

SMT allows for more creativity in electronic design. Engineers can mitigate constraints posed by through-hole mountings, enabling complex patterns and layouts. This flexibility leads to innovative designs that can enhance product functionality and aesthetics.

6. Environmentally Friendly Production

SMT generally uses lead-free solder (RoHS-compliant), resulting in a lesser environmental impact compared to older technologies that relied on lead-soldering methods. This shift not only aligns with modern regulations but also promotes a cleaner manufacturing process.

The SMT Assembly Process

The SMT assembly process can be broken down into a series of critical steps, each essential to ensuring a high-quality final product.

1. Design and PCB Layout

The journey begins with electronic design software, where engineers create the PCB layout. Software tools help simulate and optimize the design for performance and manufacturability. Key considerations during this phase include component placement, routing, and adherence to design standards.

2. Solder Paste Application

Once the PCB design is finalized, the next step is applying solder paste. This paste is a mixture of solder powder and flux, which helps in the bonding process. Automated stencil printers allocate solder paste precisely at the designated areas on the PCB.

3. Placement of Components

The placement phase involves using automated pick-and-place machines. These machines rapidly position components onto the solder paste spots. Advanced systems can identify component orientation and placement accuracy, ensuring that each component is correctly aligned.

4. Reflow Soldering

After placement, the PCBs are subjected to reflow soldering, where they pass through a conveyor oven. The solder pastes and melts, creating permanent electrical connections as it cools. This step is crucial for ensuring strong solder joints.

5. Inspection and Testing

Post-soldering, thorough inspections are essential. Automated Optical Inspection (AOI) systems often perform checks for misaligned components or soldering defects. Functional testing may also be carried out to ensure that the PCB operates as intended.

6. Final Assembly

Once inspected, the PCBs can undergo additional assembly processes, including testing and packaging. This might involve the integration of other electronic components, housing installation, or final quality assurance tests.

The Economics of SMT in PCB Production

Investing in SMT technology can yield substantial economic benefits for manufacturers. The speed and efficiency of SMT assembly reduce labor costs and turnaround times, allowing companies to respond more swiftly to market demands.

Lower production costs, combined with the ability to create smaller, more efficient devices, can lead to increased sales volume—ultimately enhancing profitability. Moreover, the flexibility in design can result in innovative products that can capture niche markets.

Challenges and Considerations in SMT

While SMT brings many advantages, it is not without its challenges. Manufacturers must consider the following:

1. Complex Manufacturing Process

The sophisticated nature of SMT requires specialized equipment and skilled personnel. Investment costs can be high, particularly for small-scale manufacturers or startups.

2. Thermal Issues

As components become more densely packed, managing heat dissipation becomes crucial. Engineers must incorporate techniques to ensure adequate thermal management in their designs, thus preventing potential failures.

3. Reliability Testing

Despite improved reliability, SMT assemblies require thorough testing regimes to prevent failures in the field. Components must endure environmental stress tests to ensure durability and functionality.

4. Obsolescence of Components

In fast-evolving markets, keeping up with component availability can be a challenge. Manufacturers must be agile in sourcing materials and must have strategies in place for component obsolescence.

Future Trends in SMT Assembly

The future of SMT technology looks promising, driven by advancements in automation, materials science, and design methodologies. Here are some trends to watch:

1. Automation and Robotics

Increased automation in SMT assembly lines is expected, thereby enhancing production efficiency and quality. Robots will play a crucial role in handling delicate components and performing tasks with precision.

2. Miniaturization of Components

As the demand for smaller electronic devices grows, the trend toward miniaturization will continue. This will facilitate the development of even smaller SMT components, pushing boundaries in PCB design.

3. 3D Printing in PCB Production

The integration of 3D printing techniques in PCB production holds potential for innovation in component design and manufacturing, enabling rapid prototyping and customized solutions.

4. Sustainable Practices

With the increasing emphasis on sustainability, manufacturers will likely adopt more environmentally friendly practices, including utilizing sustainable materials and processes in SMT assembly.

Conclusion

Surface-Mount Technology has revolutionized the field of PCB production, offering multiple advantages such as improved space efficiency, faster production times, and enhanced performance. Its ability to simplify the assembly process and support innovative designs aligns perfectly with the needs of today’s electronics market.

While challenges exist, the overall impact of SMT on electronic design and PCB manufacturing is profound, promising an exciting future characterized by rapid advancements and greater efficiency. As the electronics landscape continues to evolve, SMT will play an indispensable role, simplifying processes and catalyzing new innovations in the world of technology.